The industry of medical devices thrives on ingenuity. To bring novel ideas to fruition, it is essential to find an experienced partner who can turn concepts into prototypes, and eventually, high-quality components to be used in production. Influx Labs steps in to fill this critical role, offering a comprehensive solution to medical device companies looking for excellence in prototype manufacturing and CNC machine machining.

Influx Labs: From Dream to Prototype: Medical Device Innovation Facilitated

Medical device companies are often faced with the challenge of navigating a complicated path from initial conception to launch. Influx Labs knows the importance of prototyping in this process. They provide a safe and supportive environment to turn your innovative ideas into prototypes you can test and enables you to improve and gather feedback prior to making a decision on large-scale production.

Influx Labs CNC Machining Expertise The Potential of Precision

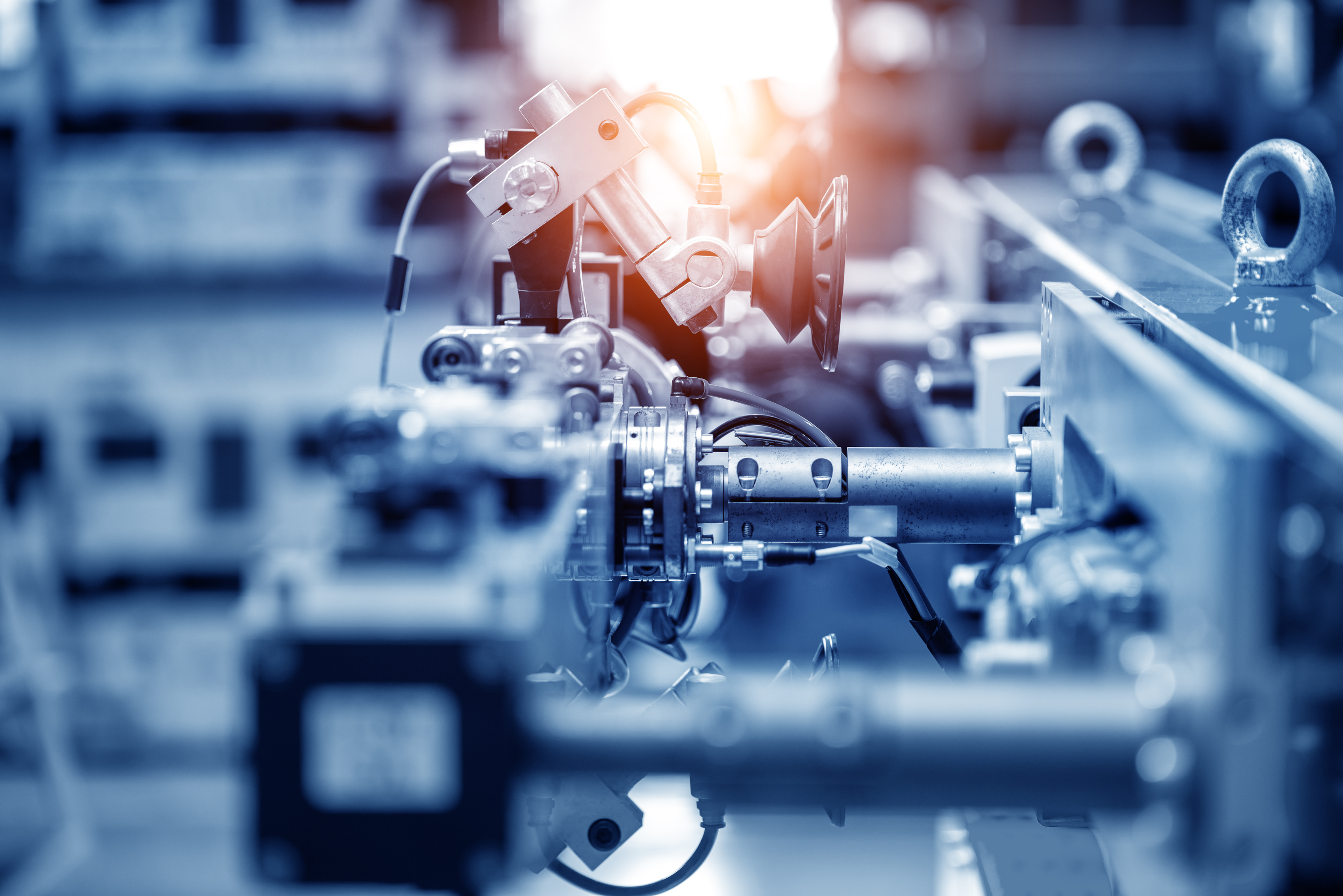

Influx Labs’ core competency is modern CNC machine tools. Computer Numerical Control (CNC) machineries employ computer-aided commands to precisely control the cutting tools. This allows for extremely precise and complex components to be made. Influx Labs is able to develop medical device prototypes as and production parts that conform to the most rigorous medical device specifications.

The Next Step is Scaling Production

Influx Labs’ services extend beyond the realm of rapid prototyping. They can seamlessly move from prototyping to production on a large scale due to their knowledge of CNC cutting. This makes it unnecessary to find a new manufacturing partner. The whole process is made easier and uniformity between the prototype and final product is guaranteed.

Certifications and traceability of the material Indefatigable commitment to quality

Influx Labs understands the importance of quality for medical devices. The company implements a strict process for complete traceability of materials during their entire process. It ensures that you are fully informed about the materials that are used in the production of your prototypes. Influx Labs will also provide certifiable materials and finishes upon request. You can rest assured that you’re meeting all regulations.

The Influx Labs Advantage: Why You Should Choose Influx Labs for Your Medical Equipment?

Several factors set Influx Labs apart from other prototyping and machining firms. What makes them an excellent partner in your medical device development:

Influx Labs has a special emphasis on medical devices. They understand the needs that are unique in this sector. They have the experience and expertise required to manufacture high-quality components for medical devices.

Precision Engineering: Their advanced CNC machining capabilities ensure consistent results and unparalleled accuracy, crucial for creating high-quality and safe medical devices.

Influx Labs is a one-stop-shop for prototyping and production. This saves you the time and effort required to find many suppliers.

Commitment to quality: Influx Labs places a top priority in quality control. From certificates to traceability of the material We ensure that medical devices you purchase conform to the most rigorous standards.

Influx Labs – Accelerating your Medical Device Development Journey

Influx Labs’ expertise in prototyping as well as CNC machining, helps medical device companies to bring their innovative ideas to fruition faster and more efficiently. Influx Labs can provide you with:

Lower risk: Prototyping helps you identify the potential issues early in the development process, minimising risks associated with production on a large scale.

Influx Labs’ streamlined prototyping and production allows you to get your medical device quicker to the market.

Improved Design Refinement: Physical prototypes facilitate the testing of your design and provide feedback to users and allow you to improve your design more confidently.

Make a partnership together with Influx Labs and unlock the capabilities of rapid prototyping as well as precise CNC cutting. Let your unique medical device ideas come to fruition and shape the future of healthcare.